Add to Cart

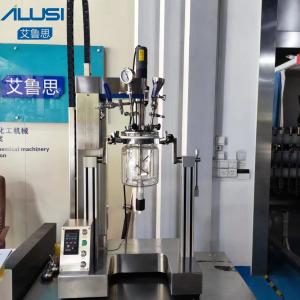

The 5L Small Lab Emulsifier High Shear Vacuum Mixer is a cutting-edge homogenizer designed for laboratories and small-scale production in the cosmetic and personal care industry. With a 5-liter capacity, this versatile mixer is perfect for creating emulsions, suspensions, and dispersions of various products such as shampoos and face creams.

Equipped with high-shear capabilities, the mixer ensures efficient and uniform blending of ingredients, resulting in smooth and stable formulations. The integrated vacuum system aids in the removal of air bubbles, enhancing product quality and appearance. Its user-friendly interface allows precise control over mixing speed and time, catering to different product requirements.

Crafted from high-quality materials, the Emulsifier guarantees durability and easy maintenance. It is a reliable and indispensable tool for cosmetic research and development, enabling the creation of superior-quality and consistent formulations for both experimental and commercial purposes.

Item NO.:ALS-10 Liter

Lead Time:15 DAYS

Shipping Port:Yangzhou/Guangzhou

Payment:EXW, FOB, CIF, DDP, DDU etc.

MOQ:1

High Shear Capability: The mixer is equipped with a powerful high-shear mechanism that ensures thorough blending and dispersion of ingredients, leading to stable and smooth formulations.

Vacuum System: The integrated vacuum system helps remove air bubbles during the mixing process, improving the quality and appearance of the final product.

5-Liter Capacity: The mixer's 5-liter capacity makes it suitable for small-scale production and laboratory experiments.

Precise Control: The user-friendly interface allows precise control over mixing speed and time, accommodating different product requirements and ensuring reproducibility.

Durable Construction: The mixer is crafted from high-quality materials, ensuring durability and long-lasting performance.

The equipment is mainly used in daily chemical care products, biomedicine, food industry, coating ink, nano materials, petrochemical industry, printing and dyeing auxiliaries, paper industry, pesticide and chemical fertilizer, plastic rubber, power electronics, other fine chemicals, etc., especially for material emulsification configuration with high matrix viscosity and solid content.

Product Parameters:

Factory:

Package & Delivery:

To ensure the quality of our service, we will follow the standard package upon delivery:

1. All products before delivery should be tested by assembly and commissioning engineers. Our salesman need to send the tested video to the customer to ensure working well of the machines. Precision parts need to be packed in film or carton.

2. All products are packed in wooden boxes. Firmly fix the edge of the foot of the equipment to adapt the machine to the requirements of loading and unloading.

Our Servers:

Ailusi provide Turn-key Project Service to customer.

1. Factory Layout design;

2. Factory Decoration based on GMP standard;

3. Formula of products;

4. Raw material etc;

5. Machine design, whole production line from A to Z;

6. Shipping service, FOB, CFR, CIF etc;

FAQ

Q1: Are you a factory or trading company?

A1: We are a factory specialized in Vacuum emulsifying mixer, filling machine, RO water treatment, capping machine and labeling machine…etc for cosmetic, pharmaceutical, chemical equipment over 20 years.

Q2: How does your factory do regarding quality control?

A2: Quality is priority. We always attach great importance to quality controlling from the beginning to the end. We support to inspect machine before shipment.

Q3: What’s the guarantee and the after service if we purchase from you?

A3: All the equipment ordered from us will provide one year guarantee from the delivery date.we could send our engineer to install or fix the machine locally.

Q4: Are your machines difficult to operate? How do you teach us to use the machine?

A4: Our machines are easy to operate, before delivery we will shoot instruction video to introduce machines' functions and to teach you how to use them.

Q5: Can you make the machine according to customers' request?

A5: Yes of course, OEM is acceptable. Most of our machines are customized design based on customer's requirements or situation.